Get started, planning your project with Powersystems

Speak with one of our high voltage electrical engineering specialists today.

Powersystems testing capability covers an extensive range of disciplines.

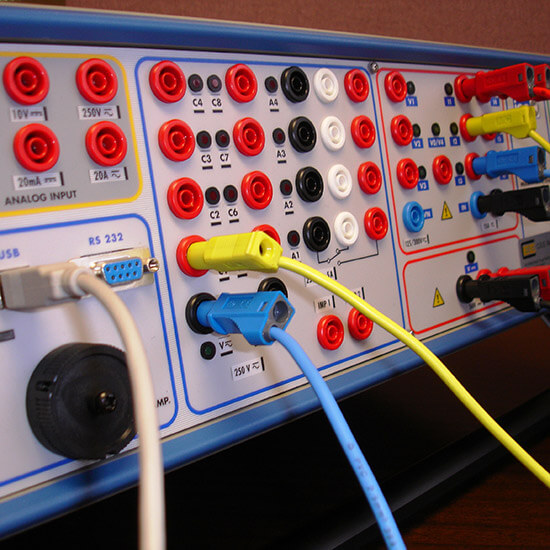

The testing and commissioning of high voltage electrical equipment is a highly specialised activity with each and every installation being tested by a trained engineer to exacting standards.

Powersystems testing capability covers an extensive range of disciplines, including cable installations, transformers, switchgear, protection, earthing and underground fault location.

Cable installations

Transformers

Switchgear

Protection

Earthing

Underground fault location

Speak with one of our high voltage electrical engineering specialists today.