Get started, planning your Anaerobic Digestion project with Powersystems

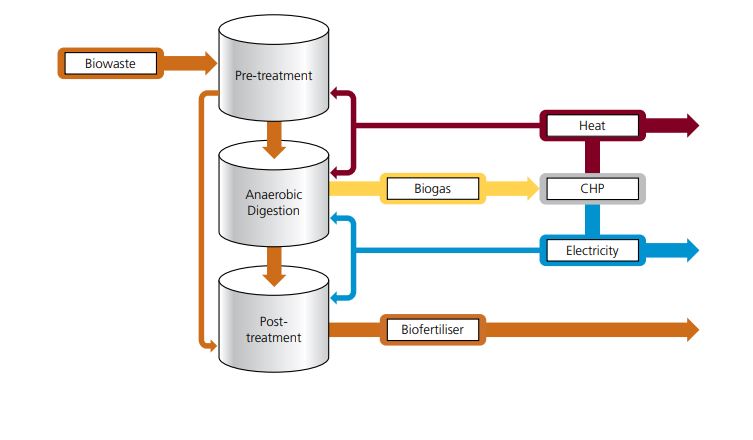

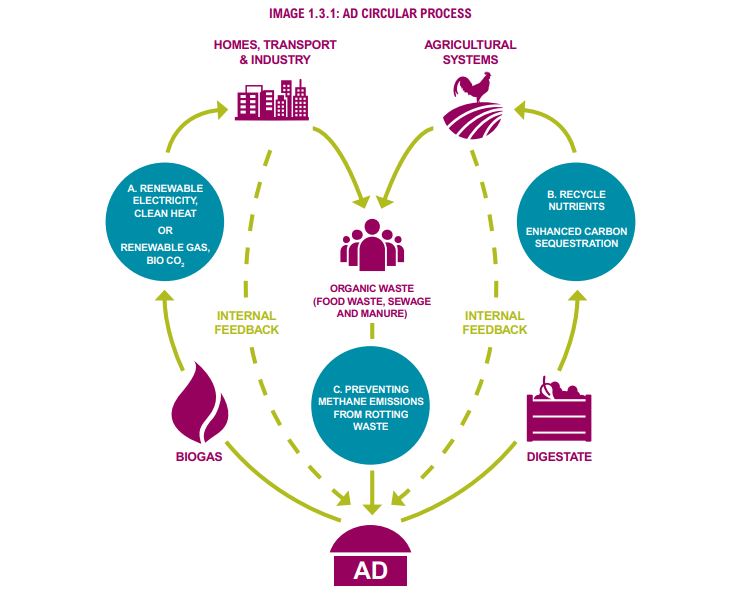

Building an anaerobic digestion plant is a large and complex project that requires teams of specialists to handle the many aspects of the project—from conception and planning to implementation.

Speak with one of our high voltage electrical engineering Anaerobic Digestion Specialists today.