| Principality Stadium Cardiff |

Project Facts and Figures

| Project Value | £200,000 |

| Project Duration | 12 weeks |

| Services | Electrical infrastructure cable containment installation and testing |

| Market Sector | Generation |

| Number of Generators | 2 |

| Generator Capacity | 2 MW |

| Total Installed Capacity | 4 MW |

| Connection Voltage | 11 kV |

| Length of Onsite Control and Signal Cabling | 3400 m |

| Low smoke cables and glands during installation | |

| The 2 generators synchronise with the grid so that any change-over of supply is quick and uninterrupted |

Principality Stadium scope of works and major design considerations:

The Millennium Stadium, known since 2016 as the Principality Stadium for sponsorship reasons, is the national stadium of Wales. Located in Cardiff, it is the home of the Wales national rugby union team and has also held Wales national football team games.

Hi-Tec commissioned the services of Powersystems to carry out the installation and testing of the electrical infrastructure for a 4 MW DRUPS system at the Principality Stadium in Cardiff.

If during a game or event the stadium was to suffer a loss of grid power or going out of voltage or frequency limits then the DRUPS system was designed to provide a reliable in-house source of back-up power.

The major items of electrical plant that Powersystems supplied and installed consisted of:

- HV circuits including HV terminations

- LV AC 230 V and 400 V power supplies for the DRUPS system

- Control circuits between panels and engines

- Screened circuits between panels and engines

- 110 V and 24 V circuits

- Network circuits for communication between panels and engines

- All cable containment for the DRUPS system

- Earthing of all circuits for the system

- Testing of all circuits

- Provision of Senior Authorised Person for switching

What is DRUPS system?

Diesel rotary uninterruptible power supply devices (DRUPS) combine the functionality of a battery-powered or flywheel-powered UPS and a diesel generator. When mains electricity supply is within specification, an electrical generator with a mass functions as motor to store kinetic energy in an electro-mechanical flywheel. In combination with a reactor or choke coil, the electrical generator also works as active filter for all sorts of power quality problems, like harmonics, RFI, and frequency variations. When mains electricity supply fails, stored energy in the flywheel is released to drive the electrical generator, which continues to supply power without interruption. At the same time (or with some delay, for example 2 to 11 seconds, to prevent the diesel engine from starting at every incident), the diesel engine takes over from the flywheel to drive the electrical generator to make the electricity required. The electro-magnetic flywheel can continue to support the diesel generator in order to keep a stable output frequency. Typically, a DRUPS will have enough fuel to power the load for days or even weeks in the event of failure of the mains electricity supply.

The main advantages of DRUPS equipment compared to battery-powered UPS combined with a diesel-generator are the higher overall system energy efficiency, smaller footprint, use of fewer components, longer technical lifetime (no use of power electronics) and the fact it does not result in chemical waste.

Principality Stadium DRUPS System

Due to several power cuts in the past the Principality Stadium decided to install their own source of power supply during events which would give them the assurance of continuity of supply whilst having the grid as a back-up. The principality stadium is one of several sites across the UK which have installed a DRUPS system providing a constant reliable uninterrupted electrical supply.

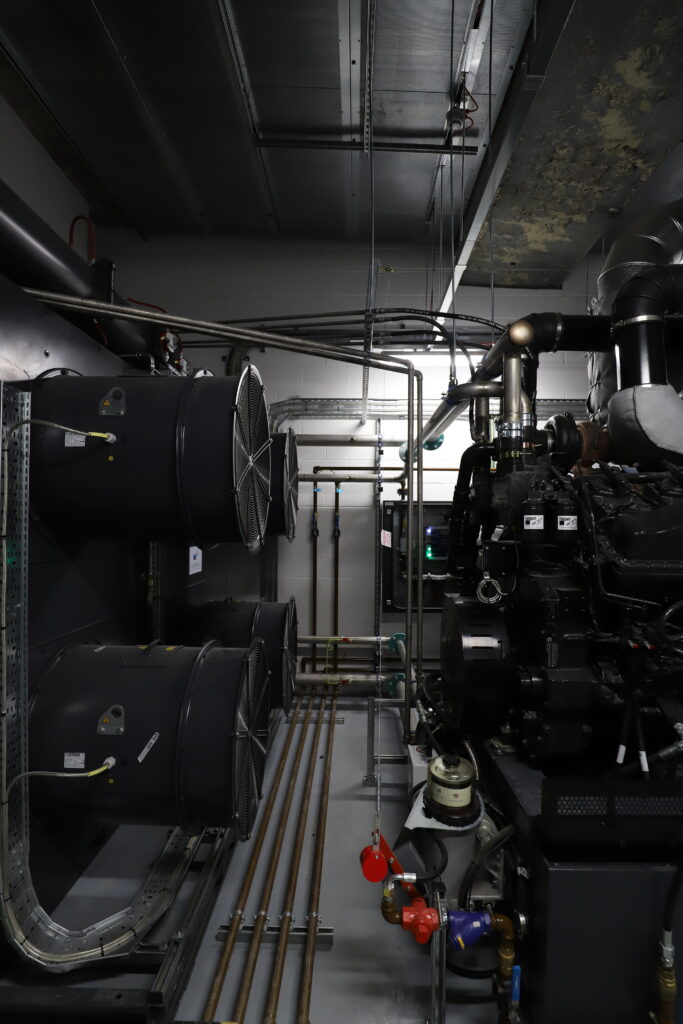

The stadium DRUPS system comprises of 2 x ‘Dynamic UPS engines’ that together create a total of 4 MW of energy. Both engine generator sets are sited in an acoustic containment room along with the HV/LV transformers. The generators are connected to a common switchboard and control system in order to provide an interface to the stadium and the Western Power Distribution (WPD) supply therefore a HV switch room was constructed next to the engine room. The engines also required a diesel supply and good ventilation in order to facilitate a fast start capability and so large diesel tanks and fans were installed as part of the project.

The engine exhaust gases are expelled to the atmosphere. The heat generated by the engines is dissipated in radiators cooled by electric fans. Diesel is not the most environmentally friendly source of fuel however the DRUPS system is only being used to provide short term reliable power at times of peak load, meaning the plant runs for short periods of time with long periods between operating times. The engines are constantly synchronised with the grid but only use the diesel as a source of supply when under load.

Powersystems partnerships:

The site is located in the city centre of Cardiff and is an iconic venue. The installation was in partnership with Hi-Tec who build the DRUPS engines and Evans electrical who were the principle contractor. Evans Electrical ran the project on behalf of the client, the Welsh Rugby Union.

The Principality Stadium hosts on average 20-30 commercial events a year including music concerts and sporting events, welcoming on average 1.3 million visitors through its doors. As the stadium uses up to 4 MW of power during an event it required a reliable source of power and back-up supply.

The site is connected onto Western Power Distribution’s 11 kV electricity network which will supply the stadium on non-event days and be used as a back-up supply whilst the DRUPS system is in use on event days.

Principality Stadium DRUPS System project timings:

Construction of Principality Stadium DRUPS system began in August 2019 and was completed in November 2019.

What the client wanted:

A reliable source of power during events

How Powersystems have helped?

Powersystems engineers were involved with designing the earthing system, the HV circuits, the cable containment and some the LV cables for the DRUPS system.

- Cable design, supply & installation

- Cable containment design, supply & installation

- HV & LV circuit testing

- SAP provision

Design works

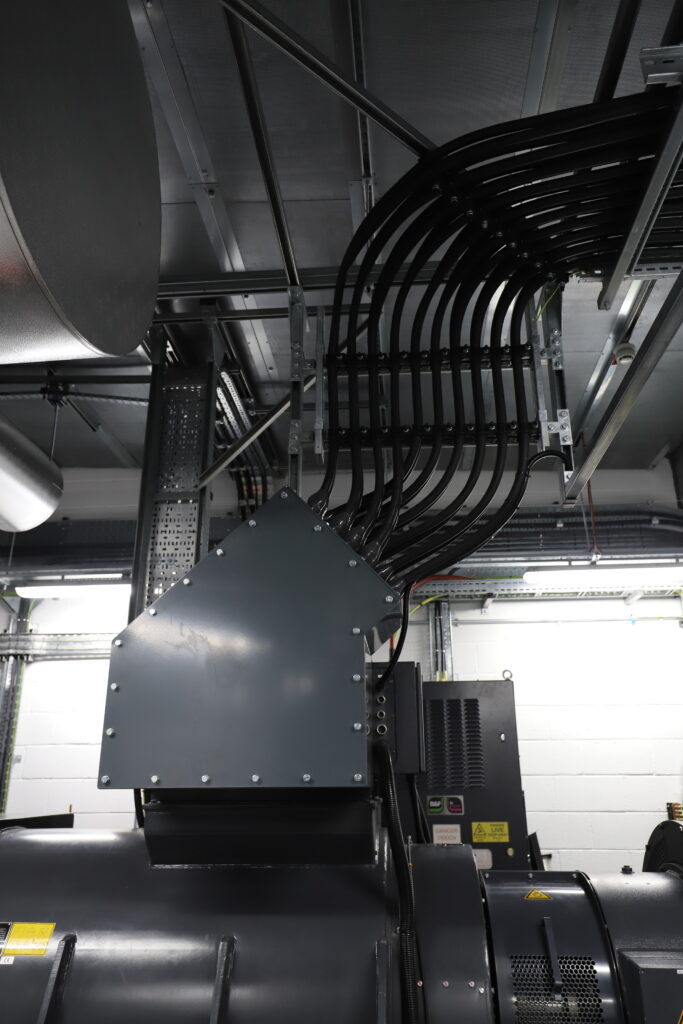

- Designed and constructed an LV terminal box for the engines which had to be angled due to a limited space constriction but could incorporate 20x 300mm LV cables.

- Designed and constructed new HV gland plates for HV switchgear to providing safer glanding of HV cables

- HV circuits

- Some LV circuits

Installation works

- Installed a new earthing terminal point for transformers

- Design and install all cable containment on ceiling, walls and across floors for DRUPS system.

- Installed all circuits for DRUPS system

Energisation works

- Powersystems provided SAP for HV switching allowing a temporary load bank supply to be used to commission DRUPS system.

- Energisation plan created for final connection to stadium HV system and Powersystmes SAP used to switch HV circuits connecting the DRUPS system to the stadium HV network.

In Conclusion:

The work was completed against constricted timescales with the DRUPS system being ready in November 2019 for the Wales rugby international verses the Barbarians.Proudly the Principality Stadium Cardiff was used as Nightingale hospital in 2020 during the Covid pandemic which would only be possible with an uninterrupted power supply.

Speak to Powersystems Today

We would love to hear from you and talk through your projects with you