Powersystems have produced a guide to Anaerobic Digestion (AD) and reducing Green House Gas (GHG)

Anaerobic digestion (AD) is a process that has been used very successfully in a large number of countries. Over many years and for a number of purposes. This includes; energy production, nutrient management, waste stabilisation, and pathogen reduction. In all of these uses, it also contributes towards reducing greenhouse gas emissions, both directly and by offset.

It is the only technology currently in the market place that meets the European criteria for second generation bio-fuel production. And can achieve this using a range of mixed wastes, not just purpose-grown biomass. It is also a technology that has been neglected by successive governments. Many of which have climbed on the bandwagons of hydrogen, ethanol and bio-diesel as the renewable bio-fuels of the future. Despite the fact that bio-gas plants using the same substrates give consistently higher net energy yields

Investment in Large Processing Plants

AD will certainly make money for those who invest in large centralised processing plants that accept high energy-value waste inputs. Also charge gate fees, and receive subsidy for the heat or power they produce.

This is not, however, a solution that will maximise the energy potential of the available waste biomass. As by far the largest tonnages of materials are animal slurries and manures produced on farms. Although the energy potential of these per tonne is low. Should they be digested on farms, the overall net energy yield is significant

An even greater benefit may be the fact that digestion can reduce greenhouse gas emissions associated with manure management and improve nutrient management on the farm.

What is Anaerobic Digestion?

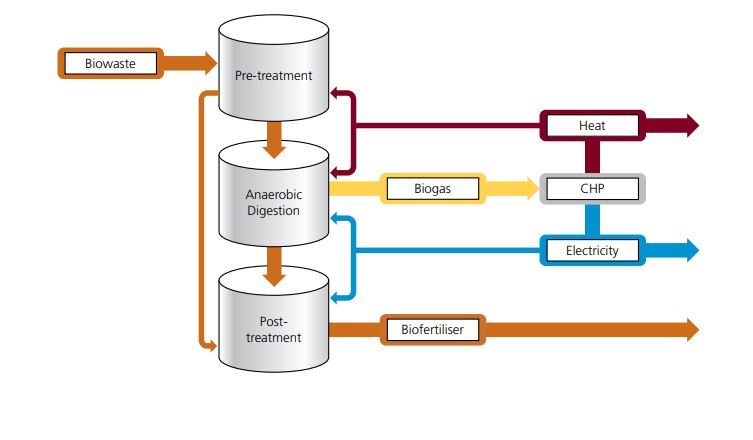

Anaerobic digestion (AD) is the controlled natural breakdown of organic materials into methane, carbon dioxide gas and fertiliser. This takes place naturally or in an anaerobic digester.

AD produces bio-gas, a methane-rich gas that can be used as a fuel and digestate, a source of nutrients that can be used as a fertiliser. Increasingly AD is being used to make the most of our waste by turning it into renewable energy.

How Does the Anaerobic Digestion Process Work?

The process takes place inside an anaerobic digester; a large, sealed tank which is void of oxygen. The air supply is restricted to stimulate ‘anaerobic’ decomposition (as opposed to composting, which takes place in the presence of air). After 20 to 60 days, depending on the configuration and internal temperature of the digester, a methane-rich ‘bio-gas’ is produced.

This gas is commonly used for electricity and heat generation, and may also be upgraded for other applications. The biomass is heated to around the temperature of blood, when it will react with the naturally occurring micro-organisms and bacteria. It goes through four stages

- Hydrolysis

- Acidogenesis

- Acetogenesus

- Methanogenesis

The end result is that the bio-gas is emitted and a residual co-product is an odour-free ‘digestate’, which is rich in plant-available N, P and K and may be directly spread on the land as a fertiliser. Alternatively, digestate may be further separated or “dewatered” into a solid fraction (typically 25-35% dry matter, enriched in P) which can be used as a soil improver, and a liquid biofertiliser containing much of the ammonium and potassium that can be pumped or transported for land-spreading.

Both the gas and the digestate material can be re-used, therefore making it a very effective way to recycle your waste materials.

Anaerobic Digestion a Renewable Energy Technology

Anaerobic Digestion (AD) is one of a number of renewable energy technologies that have become commercially available to agriculture and industrial sectors. A key attribute of AD is that it offers multiple environmental and economic benefits, particularly for UK dairy and livestock farms.

Anaerobic Digestion Plants Delivering Low Carbon Energy

Alongside their potential to deliver low carbon energy, on-farm AD plants also appear to be the most promising mitigation measure for reducing greenhouse gas emissions from manures and slurries.

Anaerobic digestion isn’t just some new fad though – this technology has actually been around since the 1800s for the treatment of sewage sludge. But, as concerns about the environment grow, so has the demand for ways to generate renewable energy and, as a result, more and more businesses have been investing in AD over the past few years.

The development of AD in Britain has been relatively slow compared to other renewable energy options, with about 125 plants operational at the end of 2013 and 500 by the autumn of 2017. At Powersystems we estimate 650 plants as of April 2019.

Feed-In Tariff (FIT) to April 2019

Up until April this year, the primary incentive available to farmers was the Feed-In Tariff (FIT), based on the installation of an AD plant if UK farmers were to change the way they handle slurry. The FIT, administered by DECC, did not encourage farmers to reduce pollution, but rather paid for them to generate renewable electricity using a combined heat and power plant (CHP) which runs off bio-gas from the AD process.

Powersystems Supporting Anaerobic Digestion and Combined Heat and Power Projects to Create Electricity

However, combining Anaerobic Digestion with Combined Heat and Power (CHP) to create electricity currently has a number of appreciable difficulties if compared with direct gas use (e.g. in a boiler). These include grid connection issues, significant extra capital/maintenance costs and plant complexity in terms of engineering a system which can continuously produce sufficient quantities of quality gas.

Powersystems can illustrate some of the benefits from on-farm AD with a number of cases studies which highlight the experience of farmers that we have worked with and how we have helped them to overcome infrastructure challenges.

Read this case study about the Farleigh Wallop AD Plant

Challenges of Slurry Utilisation

The average farmer’s options to fully and economically utilise their slurries in an environmentally friendly manner are further compromised by the fact that:

- the primary feed-stock (cattle slurry) is generally only available for 6 – 7 months when cows are housed indoors over the winter months

- sufficient year-round on-farm organic substrates may be limited

- there are significant regulatory financial penalties imposed for digesting the off-farm substrates (which have to be returned to land, anyway), including those which can be fed to cows

Barriers to Anaerobic Digestion

Some farmers may not have the option or desire to grow energy crops in order to boost bio-gas output to improve the economics of using AD with CHP, for what is primarily their slurry treatment system, especially if the cost of bought in feed increases in line with fossil fuel costs, putting further pressure on farmers to grow their own crops to feed their cattle.

A further barrier is access to capital. Pollution control and other capital grants have largely been phased out. Banks are not prepared to lend money for a technology with which they are largely unfamiliar and suspicious of.

In addition, the UK AD market has been slow to develop (compared to elsewhere in the EU), so technology suppliers of smaller plant, where margins are smaller, tend not to have a large working capital base themselves, further increasing investment wariness.

Turning Waste Into Renewable Energy

Anaerobic digesters generate significant amounts of energy from agriculture materials and waste products from the food chain. The Coalition Government identified development of Anaerobic Digestion (AD) as an early win in 2010 with a commitment to work towards a ‘zero waste economy’.

Anaerobic Digestion can play an important role as a means of dealing with organic waste and avoiding, by more efficient capture and treatment, the greenhouse gas (GHG) emissions that are associated with its disposal to landfill.

AD also offers other benefits, such as recovering energy and producing valuable biofertilisers. The bio-gas can be used to generate heat and electricity, converted into bio-fuels or cleaned and injected into the gas grid.

Bio Gas

Anaerobic Digestion can be applied to a range of natural biodegradable materials, including food waste, slurry, sewage sludge and manure.

- This material, known as biomass, is naturally broken down until it emits a new gas – known as bio-gas. Bio-gas is a methane-rich gas, comprising of around 60 per cent methane and 40 per cent carbon dioxide. This gas can then be used to generate energy.

- Bio-gas can be used directly in engines for Combined Heat and Power (CHP), burned to produce heat, or can be cleaned and used in the same way as natural gas or as a vehicle fuel.

- Bio gas can be used in stationery engines to generate electricity.

- After removing the carbon dioxide (and other trace gases using a variety of methods in a process known as upgrading) the remaining methane is known as Renewable Natural Gas or Biomethane.

How the AD process works for Food Waste

Anaerobic digestion is an alternative way of composting food waste, while also producing renewable energy and avoiding carbon emissions. The process is called anaerobic because it takes place in the absence of oxygen in a sealed tank. Like composting, it is a natural process dependent on the micro-organisms that digest organic waste.

- Collection – Food waste, collected from homes and businesses, is delivered – either directly or via a waste transfer station – to the reception hall of an anaerobic digestion facility.

- Pre-treatment – First the food waste must be pre-treated to remove contaminants such as packaging and it is also diluted with water. Heating this waste mixture to 70°C for one hour kills all pathogens in the food.

- Digestion – Now pasteurised, the waste is fed into the anaerobic digester. As with composting, bacteria break down the waste, converting it into biogas and a residue, which is called digestate.

- Energy – Gas piped from the digester is used to generate electricity and heat.

The great thing about food waste is that it is produced by a community, it’s converted to electricity and it goes back to community again – it’s self-sustaining.

Biomethane

- Is virtually identical to natural gas, the main difference is that is produced in days, rather than taking millions of years, billions of years ago.

- The uses for Biomethane are therefore as varied as are those for natural gas, for heating, cooling as a source of chemicals, fertiliser or hydrogen.

- When used as vehicle fuel, bio methane is without doubt, the world’s cleanest and most environmentally friendly fuel.

Carbon Dioxide

- Is valued for its properties as an inert gas, for heat transfer and as a solvent.

Feedstock Suitable For use in the AD process can include

- animal manures and slurries

- energy crops such as maize or rye-grass silage and fodder beet

- food processing by-products and pack-house residues

- food waste from retailers

- biodegradable household waste

What Are The Benefits?

AD provides many businesses with a way to turn the waste products they inevitable produce into new, clean energy, which can then be used on their own site. It can be utilised by any industry which produces food or sewage waste, including agricultural, sewage and food processing, and there are different sized systems available dependent on the amount of waste produced.

The methane-rich biogas which is generated can be used as a source of renewable energy to power electricity generators and provide heat. It can even be altered further and upgraded to filter out the majority of the carbon dioxide – the end result is bio-methane, which can then be used as vehicle fuel or to provide gas. Plus, the digestate can be used as fertiliser, suitable for organic farming systems.

By utilising anaerobic digestion, you can help reduce the amount of waste which you are sending to landfill. This in turn helps to reduce harmful emissions of harmful greenhouse gases, as biodegradable material which is simply sent to landfill will emit a large amount of methane, and carbon dioxide if it is simply left to rot.

How Widely Used Is This Technique?

The spotlight has fallen on waste over recent years. Currently, England generates around 177 million tonnes of waste a year – a disproportionate amount to what is reused or recycled. The government are trying to put measures in place to move towards a zero waste economy, which means that waste resources are fully valued and everything that can be reused and recycled is.

As part of this, the UK government and the European Union Directive have begun to introduce legal and financial incentives for diverting waste away from landfill, so taking advantage of this technology could even bring financial benefits for your business too.

Additionally, more people are looking to businesses to set an example when it comes to waste management and energy use. By utilising a technology which uses waste to create clean energy, you can help enhance your business’s reputation and values, reflecting your business as a responsible, conscientious company.

By investing in anaerobic digestion for your business, you will be taking a step towards making your business greener, and helping the country meet its waste disposal and energy targets

What does the UK produce that can be used in AD plant process?

The UK produces over 100 million tonnes of organic material that is suitable for treatment by AD. This includes:

- 90-100 million tonnes of agricultural by-products like manure and slurry

- 16-18 million tonnes of food waste (from households and industry)

- 7 million tonnes of dry sewage sludge.

How much energy can you get from waste?

The amount of energy produced by AD will vary depending on the material that goes into it and the particular type of digester that is used. Digesting 1 tonne of food waste can generate about 300 kWh of energy; slurry is lower yielding and purpose grown crops higher. According to the Renewable Energy Association, if all the UK’s domestic food waste was processed by AD, it would generate enough electricity for 350 000 households.

How much energy could anaerobic digestion generate in the UK?

AD could generate 10-20 TWh of heat and power per year by 2020. To put this in context, the UK’s largest power station Drax sold 27.1 TWh of electricity in 2012. AD could represent 3.8-7.5% of the renewable energy we estimate will be required in 2020.

How many anaerobic digestion plants are there in the UK?

AD has been used for many years in the UK by the water industry. It currently treats 66% of the UK’s sewage sludge in AD plants. Beyond the water industry AD in the UK is in its infancy, but growing rapidly. There are currently around 100 non-water industry anaerobic digesters in the UK producing bioenergy. You can see the locations of operational AD plants on the Biogas Map. There are many more digesters that are currently in the ‘planning’ stage of development.

Is digestate the same as compost?

No. Digestate is not compost, although they have some similar properties. Compost is produced by aerobic (with air) decomposition of biological material and digestate is produced by anaerobic (without air) decomposition of biological material. They can both be used as fertiliser under specific regulations.

Does AD smell?

There is some odour associated with the organic material that goes into a digester. However, AD can actually reduce nuisance odours as waste is delivered in closed vessels and vehicles, received in a closed reception area, and the digestion process takes place in a sealed tank. The digestion of slurry, for example, is significantly less odorous than the common practice of storing slurry in pits.

Is AD right for me?

This website is a good place to start. There is an AD cost calculator to look at the economics and there are lots of links to useful information and organisations. The key questions for a potential developer are:

- Do you have access to sufficient feedstock?

- Is there a market for the digestate?

- What do you have in terms of good access, storing and handling facilities?

- Are you willing to take on high capital project with capital rich initial period (i.e. can delayed returns be absorbed in your cash flow model)

What are the benefits of AD?

- It turns waste into a resource. Instead of sending waste to landfill, we can use it to produce energy and fertiliser.

- It produces fuel. Bio-gas can be used instead of fossil fuels.

- Fertiliser is produced. Fertilisers are made from fossil fuels. The digestate from this can replace some synthetic fertilisers.

- It reduces our carbon footprint.The methane produced during AD is burned as fuel, and therefore releases CO2 into the atmosphere. Because it comes from biomass, this does not contribute to climate change. However, if the same waste was left to degrade in a landfill site, the methane produced could escape into the atmosphere: methane has a global warming potential 23 times larger than that of CO2. Therefore, harvesting and using methane from biomass can help to prevent climate change.

- It can benefit many different people. AD potentially benefits the local community, the environment, industry, farmers and energy entrepreneurs and government.

What are the drawbacks of AD?

- AD plants are 24-hour operations and as such they need to be fed regularly. Pumps and other machinery also need to be maintained to ensure production is not interrupted.

- There can be noise, dust, and if there are leaks the potential of smells and environmental contamination. However, these issues are strictly controlled by environmental regulations, so should not occur. The liquid part of the digestate contains nitrates and other chemicals which should not be released to water but which can safely be spread to land or processed for wider use.

- The use of bio-gas also releases CO2, which is a greenhouse gas. However, this is offset because the bio-gas produced in AD replaces fossil fuels when it is used for heat, power or transport. If the waste were land-filled it would naturally rot and release methane, a potent greenhouse gas.

Notes to Editors:

Contact Information:

- This article is written by Jules Daly, Marketing and Communications Manager at Powersystems UK.

- Email jules.daly@powersystemsuk.com Telephone 01454 318000

- Photography Copyright please credit all images used to powersystemsuk.co.uk

Powersystems are powering the transition to a carbon free future

As a high voltage specialist electrical engineering company with over 45 years (1977-2022) experience Powersystems have grown by reputation to become a trusted force in the design, installation and commissioning of electrical infrastructure across the UK.

Celebrating 25 years as the first Lloyds National Electricity Registration Scheme ‘s accredited Independent Connection Provider (ICP), Powersystems are capable of delivering contestable grid connections at voltages up to 132 kV.

Since 2000, Powersystems have connected over 6 Gigawatts of renewable energy generation to the UK electricity grid, along with decarbonisation technology which includes; wind energy projects, solar, anaerobic digestion, hydroelectric, electrical vehicle infrastructure, short term operating reserve STOR, combined heat and power (CHP), Grid stability projects like rotating stabilisers, and battery energy storage systems (BESS) as well as commercial industrial private wire networks.

Working with partners, delivering sustainable power solutions, proudly the Powersystems high voltage specialist team have connected 27% of all U.K. onshore wind farm

At the core of the operation is a commitment to the highest values of health and safety, welfare, quality and the environment. Powersystems Integrated management systems are ISO accredited and their approach under their health and safety ‘Priority No.1’ brand is to aim for the best industry practice in all.

Powersystems UK Ltd. is an Employee-Owned Business and as such has a keen interest in the well-being of all its employees. They encourage and empower you to be imaginative, share great ideas and be involved in the success of the business.

Speak to Powersystems today

You can contact us as follows